Case Study

Siemens Energy Integration With Monolith

Over the last year, Siemens Energy has been using Monolith AI to help in the design process of new steam engines, focusing on the thermodynamical analysis of these new designs. The AI platform was used to learn the relationship that exists between a steam engine geometry (e.g. turbine blade) and an associated performance (in this case, the efficiency of the design).

The first step is to import the data into the platform, which can be done in many ways. The first way is to simply drag-and-drop files within the platform. But it might be more interesting to link the platform to your local network for instance, so you can access all your files quickly and safely. The files imported in this case were of different formats (3D and tabular).

Then, when all the raw files are imported into the platform, they are combined to form a data set, which is processed and exploited within a notebook. Notebooks are the main part of the platform. In a notebook, the data can be explored, transformed, sanitised, cleaned, and processed in any way. Then, this data will generally be used to train machine learning models, which will be one of the main steps of the notebook. Although the platform makes it very easy and interactive to train and find the best models, Siemens still needs an “expert” to either tune the model parameters (or use the auto-ML feature) and ensure that they are accurate and reliable.

Finally, when the model is trained and validated, it can be used in further steps in the notebook in various ways. It can be used to make new predictions instantly, to understand better your design, or to optimise it. Overall, the visuals, interactions, and dashboards are all great, and lots of valuable insights can be gained by using the models within the platform.

However, sometimes, your workflow means that it is not the best way. You might want to often and quickly call the model and use the result to make a decision, and doing so within the platform might reveal to be fastidious. This was the case for Siemens Energy.

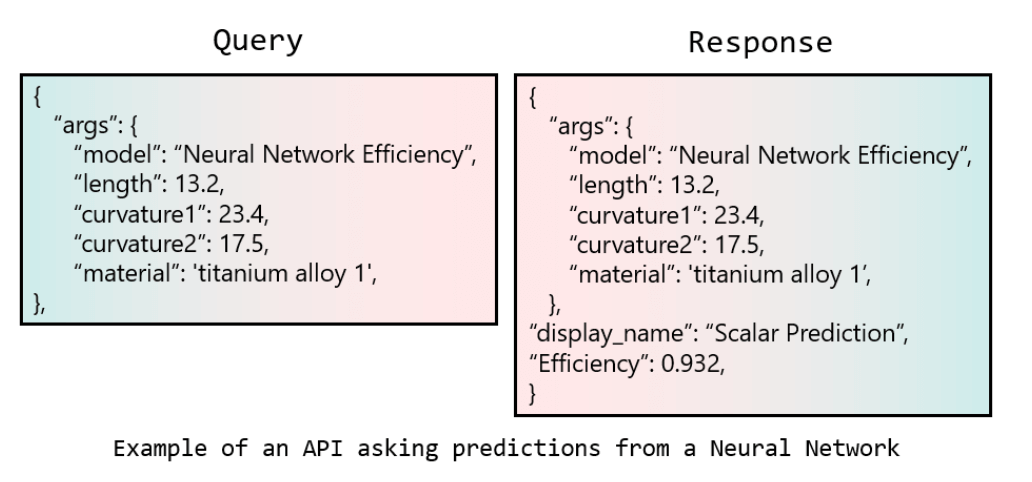

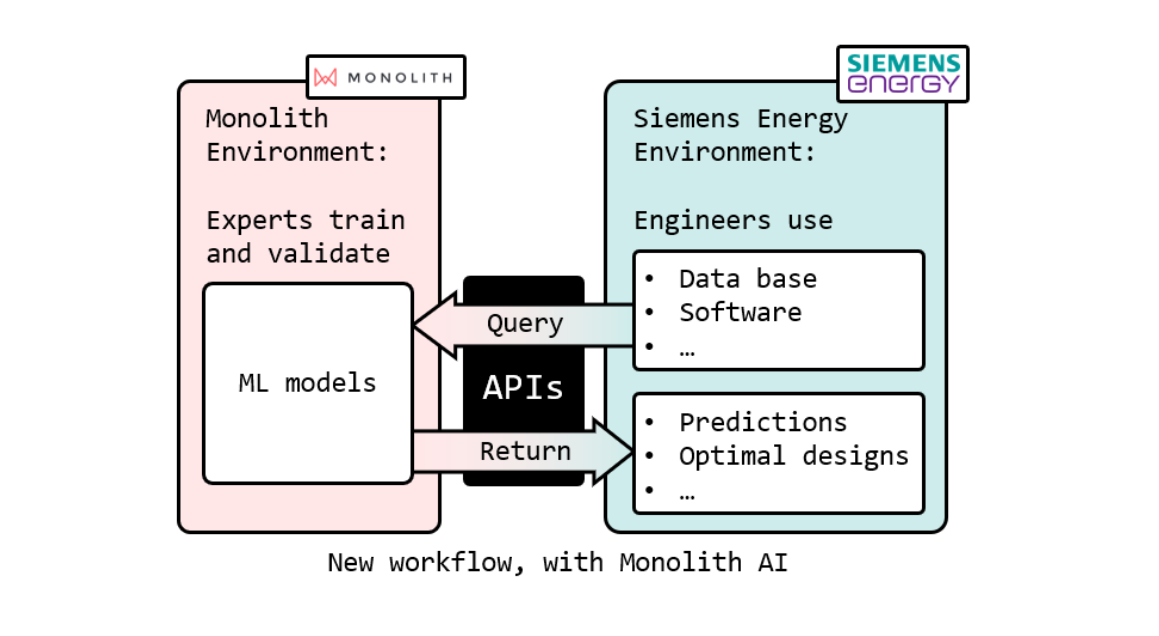

That is where Monolith APIs come into play. APIs can be directly called from your workflow (database, other software, …) which means that you can access the power of Monolith models from anywhere. The way it works is very straightforward. A query is sent in a JSON format, and an instantaneous response is received, with the initial input arguments plus the desired answer (see example in figure below).

The beauty of the APIs means that Monolith elegantly combines the simplicity and interactivity of setting up a workflow and models via the platform, with the speed and convenience of accessing results everywhere via the APIs.

Moreover, each of the two steps described above will probably be carried out by different users. The initial workflow in Siemens was that expert used to spend a lot of time helping engineers with making the right decisions. Now:

- Experts set up Monolith notebooks and train and validate models, and

- Engineers use the trained models via APIs and make project decisions automatically with AI.

This way, experts are still very much in charge of the decision-making process, by setting up the workflow and ensuring that the AI works as expected, but there are multiple advantages. First, expert time is freed as engineers can consult the AI directly, and secondly, the decision-making process is accelerated as it is automated with AI and APIs.