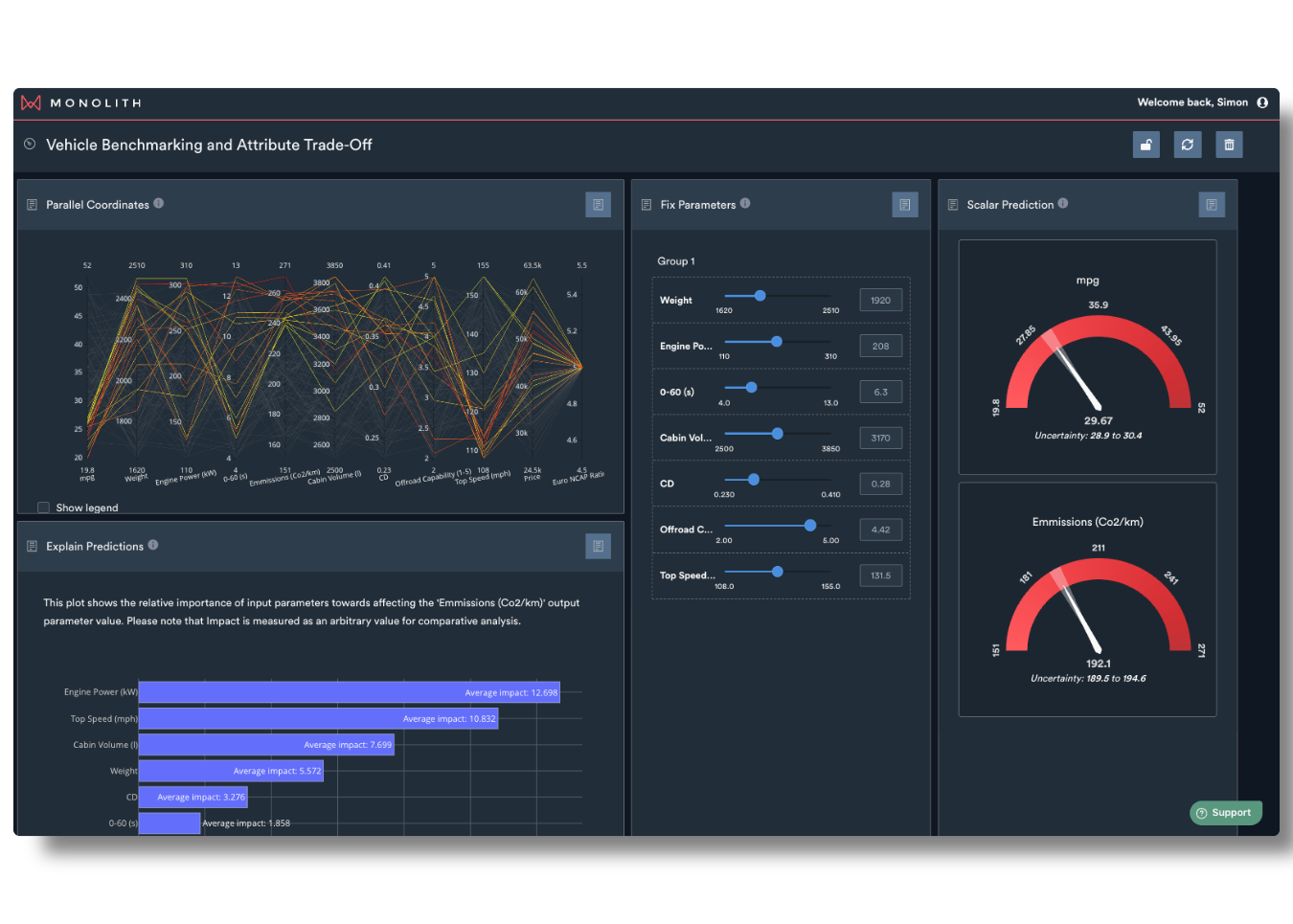

User-friendly AI tool with a notebook interface, designed specifically for domain experts.

Accelerate Battery Development

Cut battery testing time by leveraging data-driven AI models to effectively analyse and predict battery performance.

Speak to our Team

Why Monolith?

Our purpose-built AI solutions can transform your engineering workflow.

Built for engineers

Unique AI algorithms built specifically for engineering applications.

Enterprise SaaS

A scalable cloud platform for large data, high-performance computing, and collaboration.

Expert AI consulting

An experienced partner to guide AI adoption, instill best practices, and ensure success.

With Monolith tools, we found faulty assumptions, unnecessary tests conditions, and errors in our data. We discovered a completely new testing approach with AI.

-Peter, Director of Battery Validation, Major European OEM

How it Works

See what self-learning models trained from your test data can do for you.

Optimise test plans

Use Monolith's advanced algorithms to model performance and create efficient test plans with maximum coverage.

Automate data inspection

Monolith's AI anomaly detector automatically inspects and flags errors across hundreds of test data channels.

Find root causes faster

Monolith AI models help you quickly find error root causes and verify performance targets efficiently under any condition.

Calibrate complex systems

Combine test data and AI models to quickly optimize system performance across conditions and set coefficients with confidence.

Partnering with Monolith AI, we demonstrated how advanced data science and ML methods have transformed our approach to projects. By implementing Monolith’s solutions, we can process large volumes of data in minutes, uncovering valuable insights that are invisible to the human eye.

-Dr. Bernhardt Lüddecke, Director of Global Validation, Kautex Textron

Test Data Validation Feature- Anomaly Detector

Industry-proven Anomaly Detector finds more than 90% of errors faster.

- Proprietary algorithm refined with customer test applications and data.

- Find multiple error types across hundreds of channels in seconds.

- Validated on sample data to find more than 90% of known errors.

Test Plan Optimisation Feature - Next Test Recommender

Reduce test plans by up to 70%.

- Run the most important tests and skip the rest.

- Proprietary tool applies thousands of recommender algorithms to model your design space.

- Optimised and refined over multiple years on real customer test plans.

A world-leading vehicle producer trusted Monolith to analyse 500+ battery cells undergoing 18-month aging tests. Our models identified half a million USD in testing waste that could be eliminated without compromising battery selection accuracy.

-Major European OEM

Battery-Focused

Build your high-throughput battery lab with Monolith.

Reduce time-to-market without risking product safety or brand reputation. Three underlying challenges hold you back:

Test plans are inefficient

With 50–5000 channels, physical testing can take months and millions. An efficient test plan is crucial to avoid delays and under-testing.

Before Monolith, we couldn't keep up with the terabytes of battery test data generated. Now we can find subtle errors in seconds and no longer waste months on hidden test failures.

-James, Head of Validation, Cell Manufacturer

Monolith Blog

_4_w_66.png?width=66&height=66&name=BMW_logo_(gray)_4_w_66.png)