Calibrate complex systems faster for key performance requirements

Balance hundreds of input conditions and parameters. Find the best options faster. Move forward with confidence.

Request a Demo

System calibration challenges

Calibrate your system to work properly. Under key conditions. Every time.

Nonlinear systems are unpredictable

Traditional simulation tools are often unable to accurately reproduce the behaviour and performance of your designs.

Testing iterations can delay your schedule

Getting the right calibration values requires more testing. Engineers struggle to lock in decisions with confidence.

Documentation is required for product certification

Balancing multiple input values for optimal performance across multiple outputs is difficult. Without proof, you can’t ship the product.

System Calibration Module

Calibrate systems with AI-guided optimisation tools.

- Calibrate your system for better performance in less time with less data.

- Make faster decisions with greater confidence.

- Apply tailored test optimisation tools for more efficient data collection required for calibration.

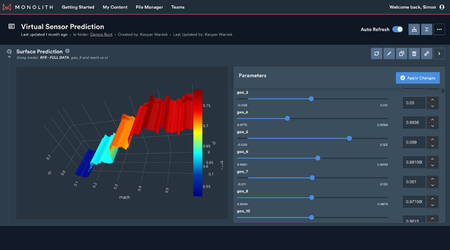

Measuring critical variables like temperatures, stresses, or emissions is often slow, expensive, or simply impractical. Engineers rely on complex dyno setups or hard-to-place hardware sensors, only to capture a fraction of real-world behaviour. Conservative calibration strategies are then used as a fallback, limiting performance and insight while adding time and cost.

How Monolith Helps

- Build reliable virtual sensors from existing test data with 20× less driving hours

- Reduce sensor setup time and hardware dependency

- Capture real-world dynamics instead of relying only on controlled conditions

- Enable smarter control system decisions in real time

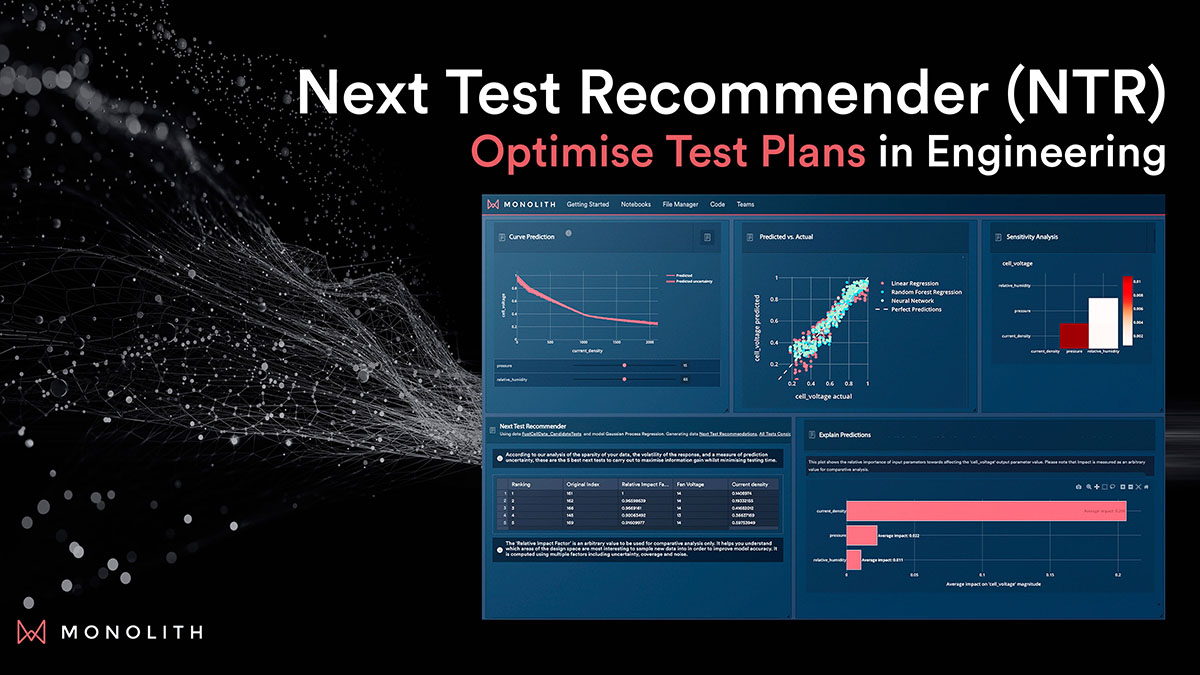

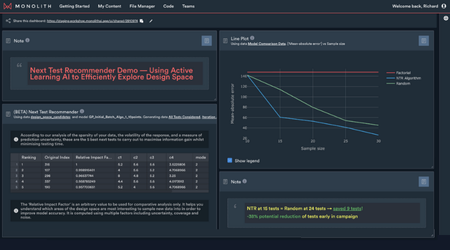

Testing consumes more time and budget than almost any other stage of development. Engineers often run dozens of repetitive cycles just to capture the right behaviours, leading to long schedules and wasted test capacity. Valuable scenarios can be buried in mountains of low-value data, delaying decisions and slowing down calibration progress.

How Monolith Helps:

- Cut total test time by up to 20× with targeted cycle design

- Capture golden datasets by focusing only on high-impact operating conditions

- Fit significantly more informative tests within the same schedule

- Enable earlier calibration and simulation model refinement

- Maintain accuracy while dramatically reducing data collection

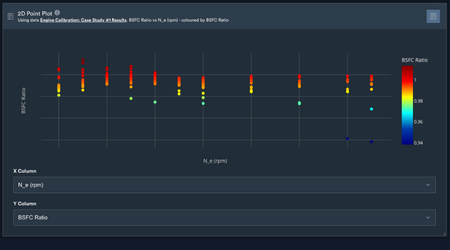

Calibration maps and lookup tables form the backbone of system behaviour, but generating them is slow, manual, and heavily reliant on scarce specialists. Engineers spend weeks filling in tables, interpolating missing values, and repeating tests across platforms. Standardisation is difficult, and scaling calibration across multiple programmes adds even more overhead.

How Monolith Helps:

- Populate calibration maps and lookup tables faster with machine learning

- Reduce reliance on manual interpolation and repeated test runs

- Empower engineers to work more independently, without constant specialist input

- Standardise workflows across teams and platforms for consistency and scale

AI for calibration applications

Three applications for AI in calibration testing

Learn how AI accelerates system calibration testing by building smarter test cycles up to 20x faster, reducing rig dependency, and improving map accuracy. This whitepaper explores three practical applications engineers are using today to reach calibration targets with greater speed and confidence.

_4_w_66.png?width=66&height=66&name=BMW_logo_(gray)_4_w_66.png)