The Intersection of AI and Engineering: A Look into the Future

In today's tough economic climate and highly competitive market, engineering leaders face significant pressure to introduce new products efficiently and cost-effectively. While the process of building and testing physical models is arduous, it becomes especially challenging in industries where complex interconnected systems become intractable to model and understand.

To address this, Monolith commissioned Forrester Consulting and today is launching The State of AI in Engineering, a study of 163 engineering leaders in the EU and US to understand their challenges and priorities during the validation and verification stage of the engineering workflow and how AI can accelerate their efforts.

Following is a brief summary of the findings. You can download the full study here:

Key Findings

Developing and validating new, complex products that are hard to model can be extremely difficult and most of the engineering leaders surveyed in the study (71%) indicated they need to find ways to speed up product development to stay competitive.

.png?width=260&height=260&name=Untitled%20design(7).png)

The number one challenge for engineering leaders developing hard-to-model products is meeting project deadlines and product launch dates. They struggle to empower their teams to be more efficient as a lack of time for innovation and creativity as well as not having trustworthy data that is properly recorded and stored prevents them from finding complex, critical patterns and insights.

The report also found engineering leaders need more meaningful insights into their testing and validation processes, with 51% saying they are running a lot of tests but not getting the insights they need.

Existing validation methods fall short (55%), and most engineering leaders (51%) don’t have the right technology to efficiently analyze test data. Talent scarcity and skills-related challenges further stifle progress.

.png?width=260&height=260&name=Untitled%20design(9).png)

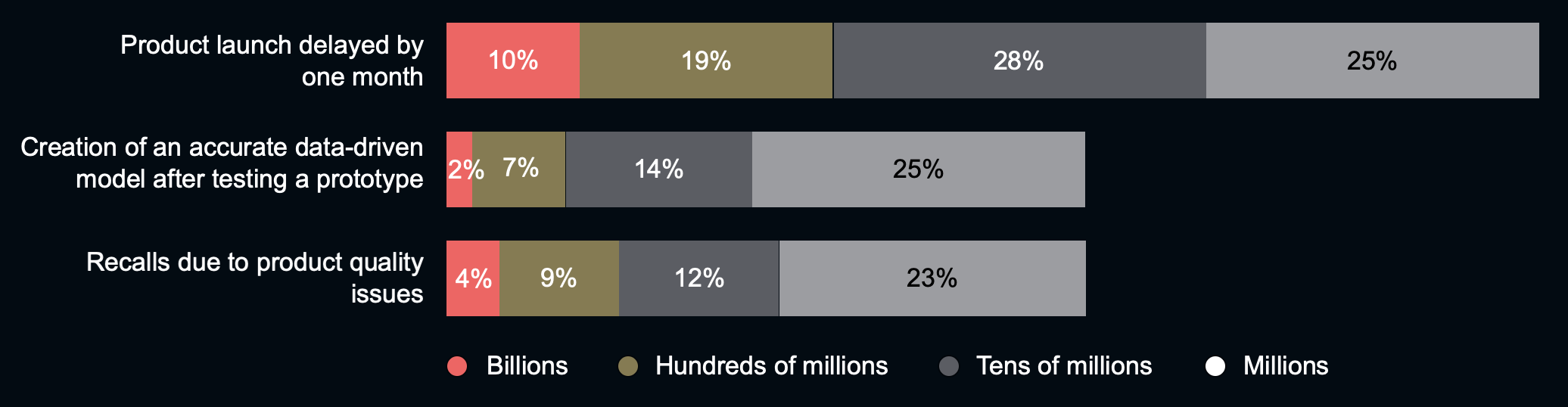

Product Delays Cost Millions$ to Billions$

Inefficient testing and resulting product delays pose a substantial financial risk to engineering leaders, costing manufacturers tens of millions of dollars. A one-month delay in product launch costs their organization hundreds of millions or even billions of dollars.

Nearly half expect millions or billions in cost each time they create an accurate data-driven model late in the process, after testing a prototype, or if they have to recall a product due to quality issues.

Valuable Engineering Data Going Unused

Only a few companies make the most of their engineering data potential, despite already having spent the time and money to gather it.

On average, only 48% use AI to analyse test data from current or upcoming products, only 29% use AI to analyse historical test data and half of all respondents don’t analyse historical test data at all.

"If your model is in your data, Monolith will find it. Built by engineers for engineers, Monolith helps you make better models faster.”

Dr. Ted Duclos

Monolith Advisor and Former CTO at Freudenberg Sealing Technologies

(quote not from the study)

.png?width=2880&height=714&name=Untitled%20design(10).png)

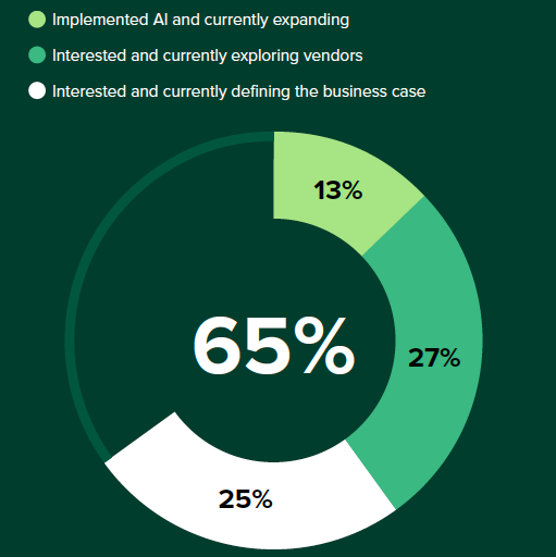

Plans to Significantly Increase Use of AI

Most engineering leaders will significantly increase the implementation of AI in their engineering workflows to accelerate product testing and gain a competitive advantage.

The majority of engineering leaders feel pressure to adopt AI to stay competitive and 65% are in the process of expanding or planning to implement AI.

AI solutions will help engineering leaders bridge the gap in talent shortages, use design and test resources more effectively, and increase the retention and transfer of knowledge and expertise.

In fact, engineering leaders already implementing AI are 43% more likely to realize increased revenue, profitability and competitiveness over those who haven’t.

Conclusion

Engineering leaders feel pressure to speed time to market and yet highly complex products that are hard to model require time-intensive, repetitive testing to validate and current methods, such as simulation, fall short.

To stay competitive, the majority of engineering leaders in automotive, aerospace and industrial markets in the US and EU are looking to AI as a means to accelerate time to market and increase engineering efficiency.

The findings in the State of AI inEngineering study highlight the urgent need for engineering leaders to evaluate how AI solutions can help them cut validation costs and speed time to market.

Download the report below or contact Monolith today to see how AI self-learning models can augment the productivity your engineering domain experts.