Fast-track validation test with AI

Improve product designs, optimise test plans, and resolve product issues faster with AI self-learning models tailored for engineering and test applications.

Request a Demo

AI-Guided Test

Test Less. Learn More.

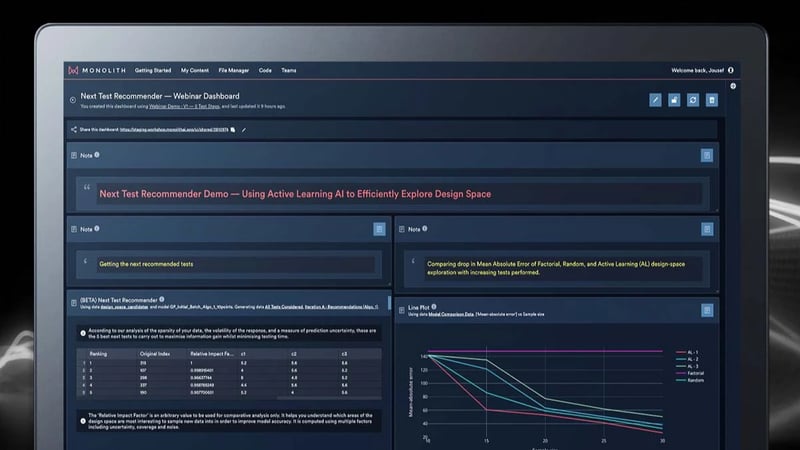

Monolith unlocks your test data to accelerate product design and validation. Refined from hundreds of AI projects with industry-leading engineering teams, we empower engineers to train machine-learning models to find hidden errors in your data, streamline test plans, find root causes of failures, and build better products - faster.

A world-leading vehicle producer trusted Monolith to analyse 500+ battery cells undergoing 18-month aging tests. Our models identified half a million USD in testing waste that could be eliminated without compromising battery selection accuracy.

-Major European OEM

Purpose-built algorithms

Proven engineering tools

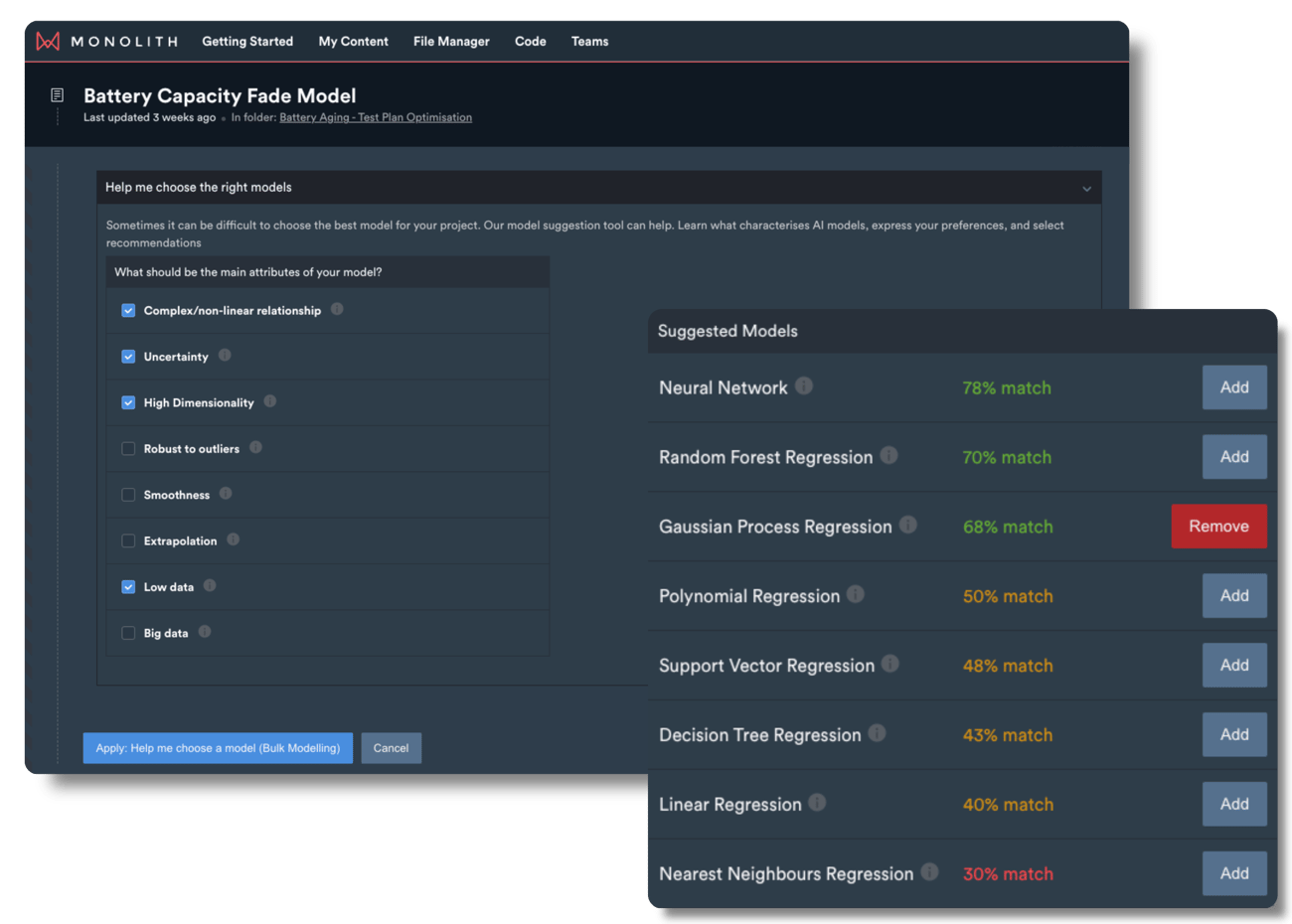

Take advantage of purpose-built tools for engineering and test-specific applications. Refined from hundreds of AI projects with leading engineering teams, Monolith algorithms are tuned to handle the real-world challenges of engineering test data.

Quickly build interactive notebooks using intuitive dialogs to load, explore, and transform your data for AI.

Train and evaluate self-learning models to quickly find the best fit, with no arduous coding or data science PhD required.

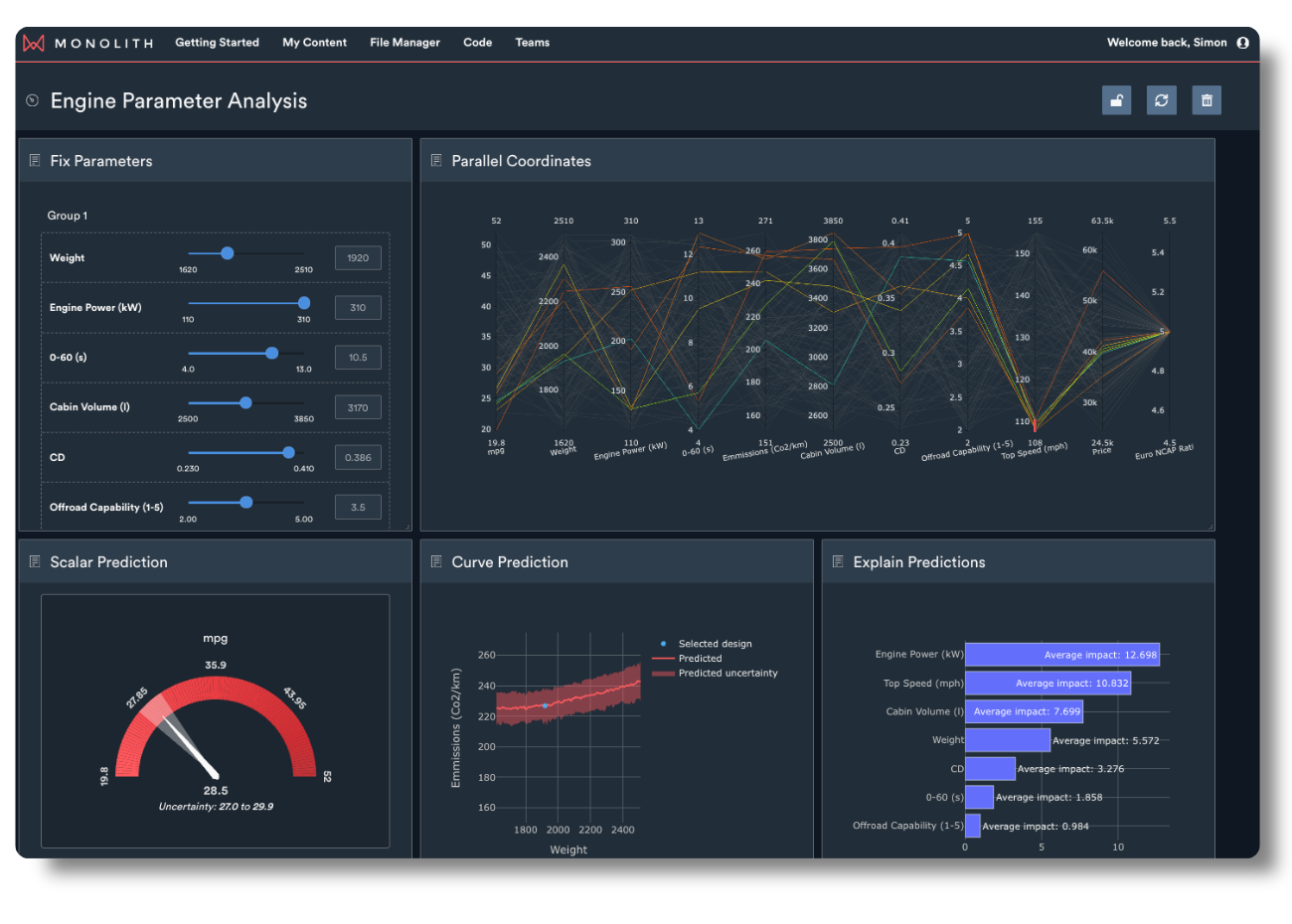

Understand how your product designs work, discover which parameters influence performance, and make predictions for any test condition.

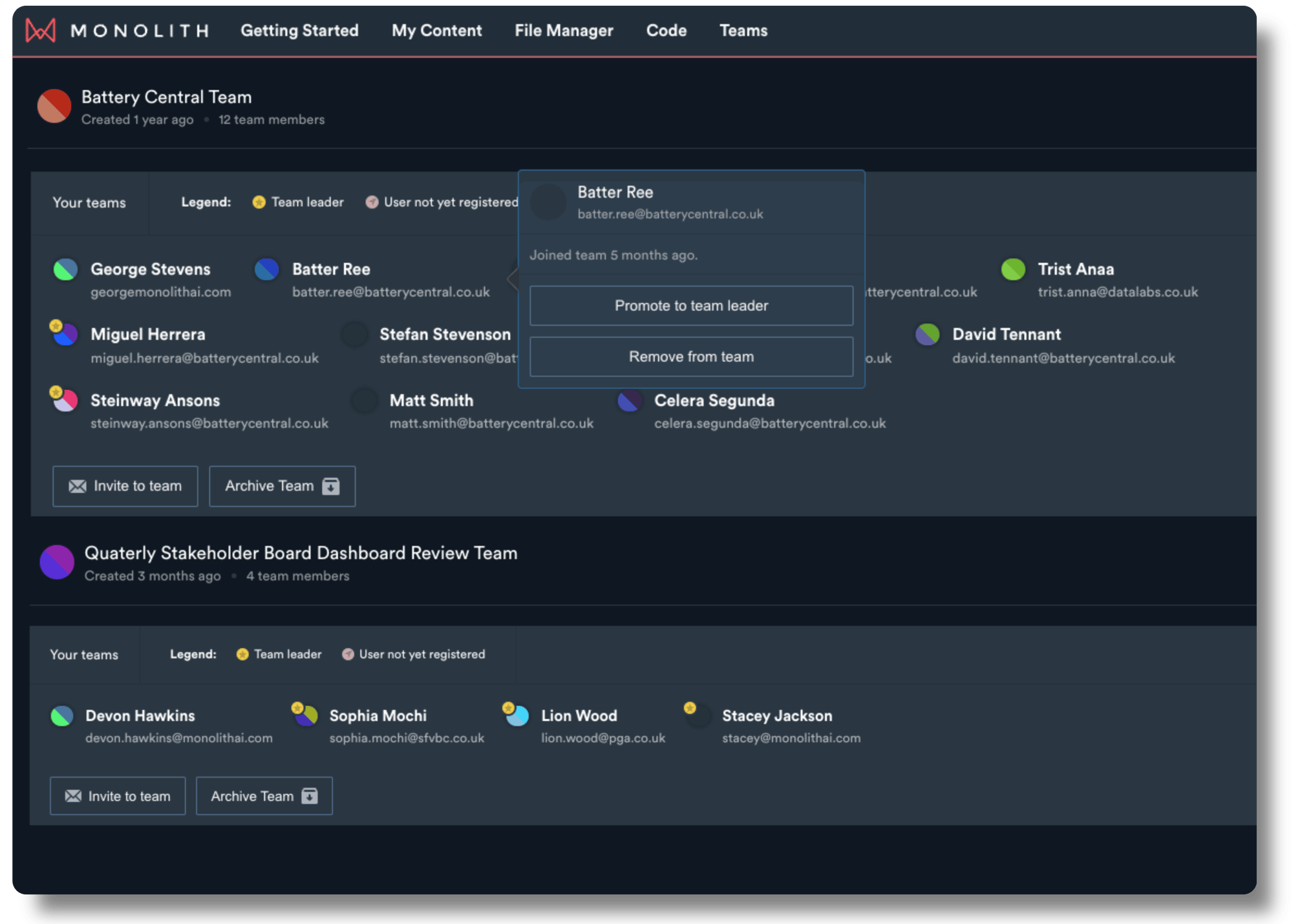

Create a dedicated space for your teams to organise and isolate data, notebooks, and models from others.

Share your insights with your team members or across your department through interactive dashboards.

Rest assured that your data is protected with industry-standard security measures, data encryption, ISO 27001, and access control.

Leverage the cloud for large data sets and advanced computing power to grow as your expertise and requirements grow.

Embed and automate AI models into your engineering processes and tools to realise value and scale from your work.

With multiple configurations and install options, quickly adopt AI without in-house development and infrastructure issues.

Train and upskill your team with in-product tutorials, online learning tools, and custom training options.

Leverage the Monolith tools and expertise from hundreds of AI projects with leading engineering teams worldwide.

You choose the appropriate service level needed to get projects up to speed quickly and ensure long-term adoption and success.

When a global vehicle producer needed to optimize their B-sample battery aging tests, Monolith's machine learning validated the engineers' intuition with hard data—giving management the confidence to cut half a million USD in low-impact test points. These were the options we chose.

-Major European OEM

Monolith resources

Learn more about AI applications in engineering

_4_w_66.png?width=66&height=66&name=BMW_logo_(gray)_4_w_66.png)