Product Overview

No-code AI software built for engineers.

End-to-end cloud platform enables any engineer to use their test data and expertise to solve intractable physics problems.

Get in Touch

Request a Demo

An AI workbench designed for engineers

- No-Code AI for engineering

- Engineering-specific algorithms

- Scalable cloud platform for the enterprise

- Guidance from engineering experts

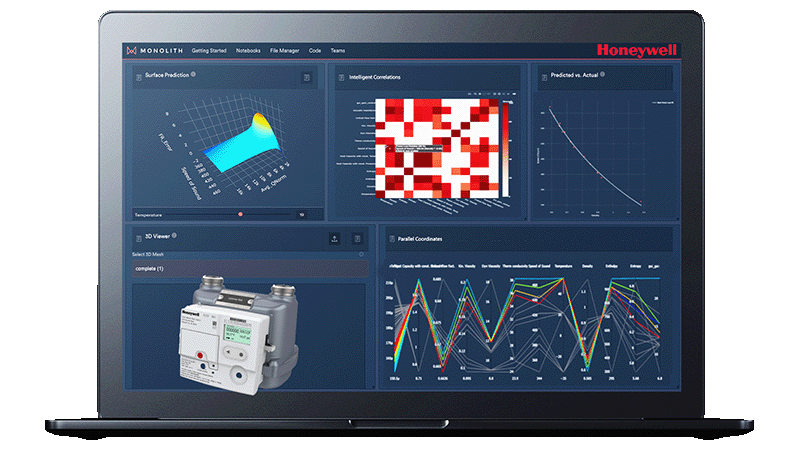

- Quickly design AI pipelines and train models without advanced programming or data science experience

- Understand how your design works and which parameters are most influential on performance

- Use AI self-learning models to make predictions on how your design performs under different conditions

- Find optimal values for key design parameters to meet performance targets and regulatory requirements

- Analyse, visualise, and transform your data using intuitive charts, graphs, and analysis routines

- Apply advanced AI models for solving engineering and test challenges including optimising test plans, inspecting data, and calibrating systems

- Make predictions on time-series waveforms using specially designed AI models

- Take advantage of cloud scale for big data and advanced computing power without requiring IT resources, data engineers, or DevOps teams

- Build interactive dashboards to share knowledge and outcomes with colleagues

- Integrate AI models into your engineering workflow with APIs

- Partner with our experienced services team to guide your team through the AI adoption journey

- Learn from best practices and common pitfalls from more than 300 AI projects with top engineering teams

- Upskill your team with customised AI training and consulting from our experienced engineers

How it Works

Learn how Monolith works with your data

- Import data from files or databases

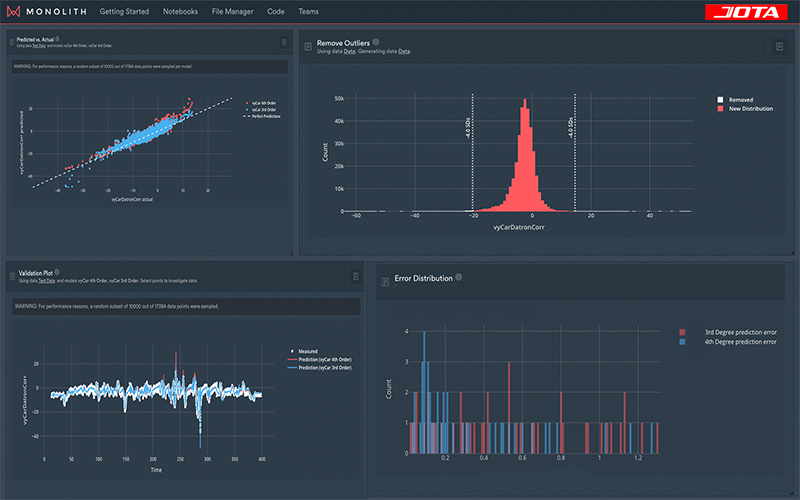

- Explore your data with analytics and visualization tools

- Transform your data for optimal AI modelling

- Model your designs using powerful AI algorithms

- Evaluate different modelling options for best performance and accuracy

Why use Monolith's no-code AI platform?

Test Plan Optimsation

Using test data to train advanced machine learning models, you can analyze product behaviour to find the most critical test conditions required to validate your design.

- Run the most important tests and skip the rest

- Optimise resources spent on costly test rigs and facilities

- Validate your designs faster with fewer prototype iterations

Test Data Validation

Apply powerful AI models to your raw measurement data to automatically inspect for errors. One failed sensor or wiring malfunction can render thousands of dollars in testing useless. Stop wasting your engineers’ valuable time on manual inspection of test data.

- Find outliers in your data fast with intuitive visualization

- Catch bad data now to avoid re-engineering later

- Ensure your data is clean and accurate for optimal AI modelling

Root-Cause Analysis

Pressure on engineers is high to identify critical parameters causing failure, quickly analyze the root cause, and predict how the product will perform in changing conditions. Using AI models of your design, you can gain deeper understanding of key factors that may be causing failures.

- Predict what design changes are most likely to fix failures

- Identify components causing suboptimal performance

- Avoid long delays and uncertainty in the validation process

System Calibration

Designing highly complex, non-linear systems that must meet stringent performance standards or regulatory requirements is a challenge. Predicting which combination of inputs will deliver the optimal output, in all operating conditions, is next to impossible. With AI self-learning models, you can apply powerful optimization algorithms to calibrate performance parameters for key conditions.

- Calibrate complex dynamic systems faster and more accurately

- Ensure your system or product performs to specifications in all conditions

- Find best-fit values across 1000s of input ranges and operating conditions

Monolith AI Features

No-Code AI for Engineers

Use your engineering data to create accurate self-learning models, deploy AI models, and quickly understand and instantly predict the performance of your complex system - no advanced programming experience or PhD in data science required.

Engineering-Specific Algorithms

Monolith includes unique AI algorithms to solve specific engineering and validation challenges based on more than 300 AI projects with top engineering teams. Get to market faster with AI tools custom-tailored for engineering test challenges.

Scalable SaaS Platform

Monolith is a cloud-based application that scales for your data and computing power needs. Share your knowledge with teammates through collaborative dashboards and integrate them into existing engineering workflows to accelerate product development and testing.

AI Consulting and Implementation

Adopt best practices through AI training and guidance from our experienced services team. Upskill and complement your team to ensure success in adopting AI in your engineering process.

On-Demand Webinar

Battery testing with AI:

Build a more efficient test plan you can trust

In the first part of the EV webinar series, we reviewed the latest research on using AI models to significantly reduce the testing needed for EV batteries. In this follow-up webinar, we’ll show how to implement these concepts using Monolith software.

"If your model is in your data, Monolith will find it. Built by engineers for engineers, Monolith helps you make better models faster."

Dr. Ted Duclos, Monolith Advisor and Former CTO at Freudenberg Sealing Technologies

Our Industries

Top Monolith industries

Monolith AI empowers engineering domain experts in automotive, aerospace, and industrial markets to reduce expensive, time-intensive testing, reduce risks to product performance and quality, and cut product development time.

News Center